Clogged pipes and spray nozzles, deposits on heating elements, solar collectors, and cooling surfaces of humidification systems are well-known issues. Additionally, the insulating effect of limescale negatively impacts the heat transfer of heating elements and heat exchangers. Even a limescale layer of just 2.5 mm can result in a 25% efficiency loss, which is reflected in higher energy bills.

Removing limescale is labor-intensive and often requires production lines to be halted.

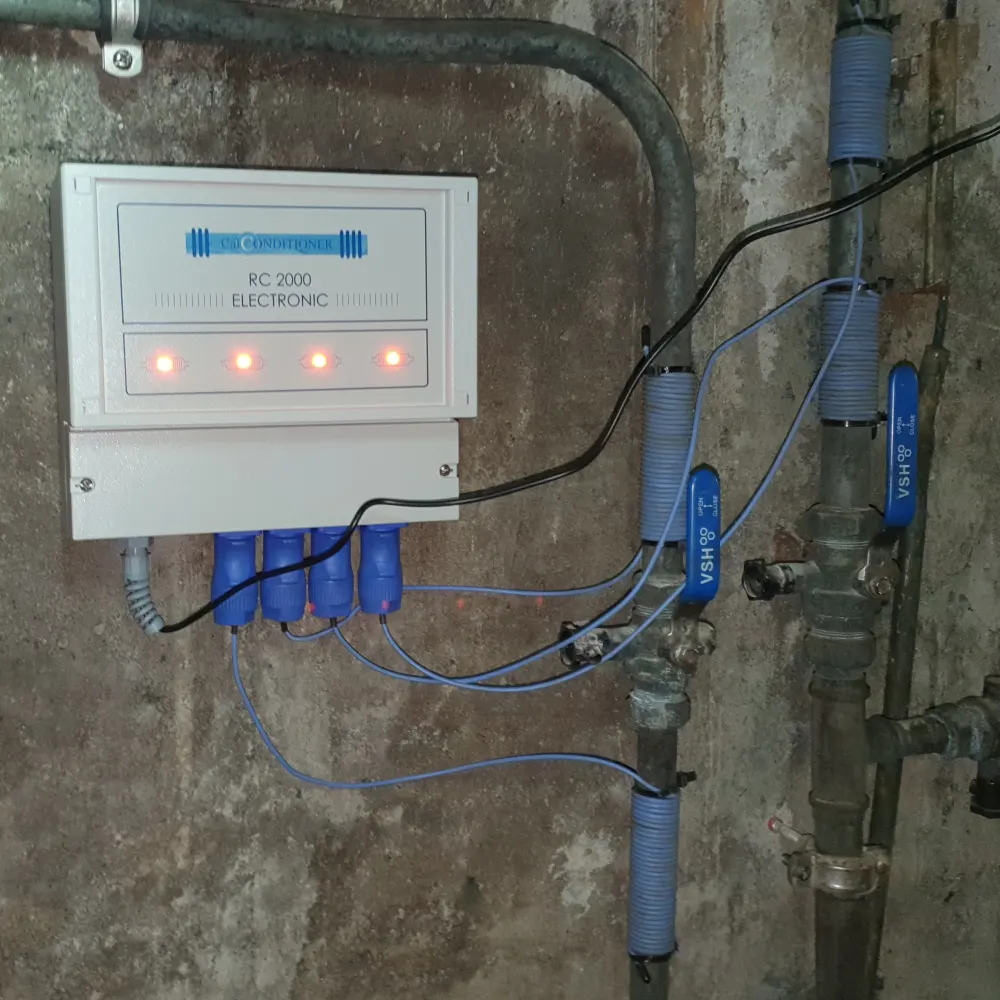

The Calconditioner water softener RC2000 is designed for industrial applications as well as for hospitality, multi-use in apartment buildings, and residential units. Thanks to its ABS housing (with an IP65 protection rating), this water softener can even be installed in dirty, humid, and hot environments.

Coils are custom-made and supplied based on the pipe diameter.

Principle of Operation for Electronic water softeners

Electronic water softeners use electromagnetic or electrostatic fields created by coils wrapped around pipes. This technology has been used in industries for decades and works by influencing the behavior of calcium and magnesium ions. Here is how this technology works and why it is popular in industrial applications:

- Induction of alternating electromagnetic fields: In electronic water softeners, coils are wrapped around the water pipe, generating an alternating electromagnetic field when current flows through them. This field influences the dissolved minerals in the water, such as calcium and magnesium ions, keeping them in a continuous state of slight charge alteration.

- Change in crystal formation: The alternating electromagnetic fields affect the way calcium carbonate crystallizes. The field promotes the formation of aragonite, a form of calcium carbonate that is less likely to adhere to surfaces than calcite. Aragonite often remains in small, insoluble particles in the water and can be flushed away with the water flow.

- Reduced adhesion to surfaces: The electrostatic charge generated by the electronic fields also reduces the tendency of limescale to adhere to surfaces. Due to the charge, calcium carbonate particles are more likely to remain in suspension rather than depositing on pipes or heating elements. This significantly reduces the formation of hard limescale deposits.

Benefits in Industrial Applications

Prevents limescale buildup without chemicals: Electronic softeners are popular in industries because they do not require chemical agents to reduce limescale, which is especially important in environments where water is reused for production or cooling.

- Low maintenance: With no moving parts and no need for regeneration with salt or other chemicals, the system is highly attractive for large installations with high water throughput.

- Effective at higher flow rates: In industrial applications where water flows rapidly through pipes, electronic treatment proves effective at keeping limescale particles in suspension.

Conclusion

Electronic water softeners have proven their value in industrial settings by reducing limescale without the need for chemical agents.

Technical specifications:

| Capacity |

9000 liter / hour |

| Diameter |

28 tot 42 mm |

| Usage |

10 Watt / hour |

| Width |

213 mm |

| Height |

185 mm |

| Depth |

84 mm |

| Material |

ABS |

| Type |

IP65 |